Laser Processing Service

We manufacture and supply laser processing parts for finished cars and starting cars,

and we have a production structure that can respond quickly to customers' needs with excellent quality and productivity.

SIS Co., Ltd. has laser welding, cutting, and hybrid systems for producing laser-processed parts for final and prototype automobiles.

With expertise on laser processing equipment fabrication, we produce parts with high quality and productivity to quickly respond to customer needs.

- Tailored Blank Welded Blank supply

- Hot Formed Tailored Blank Welded Blank supply

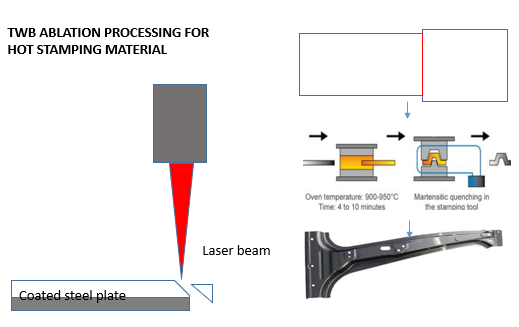

- Laser ablation process service for hot stamping parts

- Laser welding for sample & mass production part.

- Laser cutting for mass production part.

- Laser technical support

- Hybrid welding service

Body parts for increased safety and weight reduction

Specialized laser processing technology of SIS applied to various body parts

TWB stands for Tailor Welded Blank, and TWB technology is a series of technologies that make parts by cutting and welding iron plates of various materials and thicknesses into necessary shapes, as if cutting suits.

HFTWB adds heat to existing TWB technology to strengthen the material through the Hot Stamping process, demonstrating higher weight and reliability than existing TWB BLANK.

SIS Co., Ltd. is a company that makes equipment with the above technology and has various patents and technologies, so it has high productivity and can produce high quality products.

We are already supplying various parts at reasonable prices with many domestic and foreign companies, and we are showing high satisfaction.

1) Total Machine Nos : 5 machine.

2) Welding table size : Max 3600mm x 2000mm

3) Welding thickness : 0.6~2.5mm

4) Welding length : Max. 3200mm

5) Laser welding power : 4 ~6 kw Fiber laser Nlight

6) Seam tracking unit

7) Bead inspection unit for upper and bottom

1. Mass and flexible production

Three auto laser welding lines can produce an average of 9,000 sheets/day.

One manual laser welding line can weld products in different shapes.

2. Thorough quality control

The real-time laser camera welding bead system detects product defects.

It carries out thorough welding inspection for every lot.

3. Special equipment

We fabricate and deliver a TWB laser welding line so that we can professionally operate welding conditions and equipment for laser welding.

We have TWB laser welding experts with rich experience.

4. Quick and accurate product delivery

Special operators and the SIS special laser welding system minimize the production time by quickly finding welding conditions for new materials for quick delivery.

Products can be delivered to you anytime you want.

5. Competitive price

Competitive price for high-performance optimal equipment to reduce incidental production costs.

Price competitiveness with labor cost saving through automation

- Tailor-welded blank (TWB) automotive chassis steel sheet door INR, pillar, hood, floor, etc.

- 3-D shape laser welding and cutting

- Processing machine case, and large steel sheet welding and cutting

- Part processing for automotive, medical, and heavy equipment

- Automotive seat frames, transmission (power trains), and polly

- Pipe, tube, and pulley welding

- Fuel cell battery welding

- Overlap, fillet, and butt joint welding

- Large-/small-quantity and prototype production